Tungsten Inert Gas (TIG) or Gas Tungsten Arc Welding (GTAW) Process

The TIG or GTAW is an arc welding process that uses a non-consumable tungsten electrode to produce the weld. The weld area is protected from atmospheric contamination by argon, an inert shielding gas.

The TIG method is a good alternative when the oxyacetylene process is not suitable for the base metal, when carburization deteriorates corrosion resistance or when hardfacing a large part. The heat of the process is more localized than the oxyacetylene flame, but not so fierce as the metal arc. The TIG process produces clean deposits with minimal dilution (5-15%) with the base metal. The technician has a high degree of control over heat input and the positioning of the arc and weld deposit.

The surface of the part to be hardfaced must be free from rust, scale, grease, dirt and other foreign materials. Preheat and post-heat the work according to Table 1 to minimize the possibility of cracks developing in the deposit or base metal.

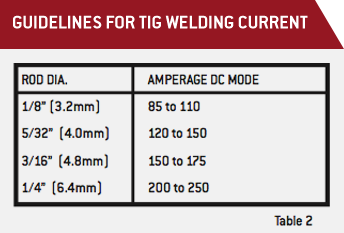

DC electrode negative (straight polarity) is always used with the largest tungsten electrode possible to minimize tungsten contamination of the weld pool. Recommended nominal current settings are shown in Table 2.

STAY CONNECTED